Pair of forks with an integrated weighing system for lift trucks, easy to use, sturdy, and reliable. The optional wireless indicator to install in the cabin makes weighing operations easier and has a large range of accessories. Operates by a rechargeable battery or directly powered from the lift truck. Compatible with any lift truck having a DIN 15173 - FEM fork holder plate, of the IIA (IIB optional) or IIIA class. Available in CE-M approved version.

|

|

|

MAIN FEATURES

|

|

|

- Mechanical characteristics:

- Painted steel forks.

- Each fork weighs: 75kg (LTF25) and 90kg (LTF50).

- Functions with 4 shear-beam IP68 load cells.

- Accuracy: +/- 0.2% of the capacity.

- Max. allowable overload: 200% of the nominal capacity.

- Max. horizontal inclination (oscillation): +/- 2° with the same accuracy characteristics

PACKAGING IS INCLUDED IN THE PRICE

for the complete protection against scratches and bumps during transportation. The weighing forks are shipped inside a sturdy wooden case which is custom made.

This special service is included in the price of the product.

Electrical characteristics:

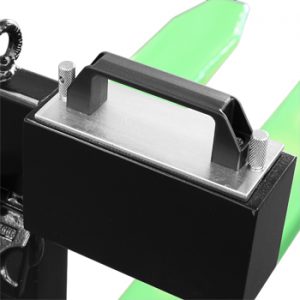

- Weight indicator, integral to the weighing forks, with waterproof 5-key numerical/functional keypad, 25mm backlit LCD display with 6 high contrast digits, protected by a thick steel case.

- Overall IP rating: IP65. IP68 load cells.

- Digital Calibration and Set-Up via keypad or PC with DINITOOLS.

- Power at the forks provided by a rechargeable battery with an operating time of about 40 hours or continuous use via an additional battery kit (optional).

- Programmable automatic switch-off.

- Battery charger supplied.

|

|

|

|

CABIN INDICATOR FUNCTIONS

|

|

|

- Repeater kit model DFWKBTHF (optional):

same functions as the indicator integrated with the forks, but additionally: memory for 30 tare weights, 2 numeric IDs, keypad lock, repetition of last printout, quick manual input of tare, target, PMU, thresholds and set points.

- Indicator kit model 3590KBTHF (optional):

If this kit is used, the indicator integrated with the fork transmits the weight to the touch screen terminal in the cabin, which offers specific advanced features according to the program selected:

- AF01: totalising/order picking

- AF02: piece counting/quantity

- AF05: totalising and labelling

See the technical details of each program for more details.

|

|